c h r o n o l o g i c a l

g u i d e

> Year 1 Year 2 <

> Year 3 Year 4 <

> Year 5 Year 6 <

> Year 7 Year 8 <

> Year 9 Year 12 <

fetching & dismantling

sandblasting & evil rust

right "b" pillar

fixing right inner sill

basic body repair, por-15

frame removed, footwell repair

hole fixed, car flipped, etc.

sill stiffeners, rear bulkhead, etc.

various small parts

left sill, added stiffener, etc.

- lousy weather

trunk floor (reprise)

right floor, left sill, etc.

left floor, wheel well, etc.

right upper wishbone

floor done, car righted

rack, front frame, evil rust

left door cleaned & fitted

right door, right suspension

bonnet, part 1

bonnet, part 2

bonnet, part 3

bonnet, part 4

bonnet, part 5, etc.

bonnet, part 6

bonnet, outer sill, etc.

lots of stuff

left side, bonnet internals

frame, bonnet attached

engine stand, oil pan removal

pistons removed, sanding

sanding, final filling

color, frames, primer

brushed primer test

2nd coat primer

holiday greetings!

finish prep, detail on dent fix

spraying primer

winter chores

1. undercoat, plating prep

2. plating, spraying color

bonnet, plate prep, cylinder head

cylinder head paint, bushes

plating saga

front frame, suspension, part 1

front suspension, part 2

front suspension, part 3

priming and painting

bonnet, part 7

painting color!

boot lid, steering wheel

gas tank

winter chores

1. firewall sundry

2. front suspension

3. steering setup

4. master cylinders/pedals

5. the rest

data plate screed

winter to spring

1. irs rebuild

2. trunk floor, harness

3. data plate (again)

data plate, door, headlights

dash vinyl, crosshatch aluminum

windshield, right door

interior, "widget"

chrome parts!

door handle details

rolling chassis

molasses rust removal

electrical, part 1

bores, thrust washers

new engine!

head differences

block differences

compression ratio

engine in place!

alternator

catchup & photos

it runs!

setback and brakes

darned close & engine diffs

driven

top and seats

driving and little stuff

|

|

|

Bores and thrust washer damage

I've been picking away at the engine. The cylinder head has gotten a clean bill-of-health after inspection, pressure testing, and a shave. The SU carburetors are cleaned up,

though not quite ready since replacement parts are needed. Bores are all measured, and they have little wear from the last rebuild, when .030-upsized pistons were installed.

I have debated whether I should just go ahead and have new sleeves fitted and go back to the nominal bore of 3.4252". Since the current bores are still in good shape, I think I'll

wait to do the more thorough rebuild. I'll fit new rings on the old pistons.

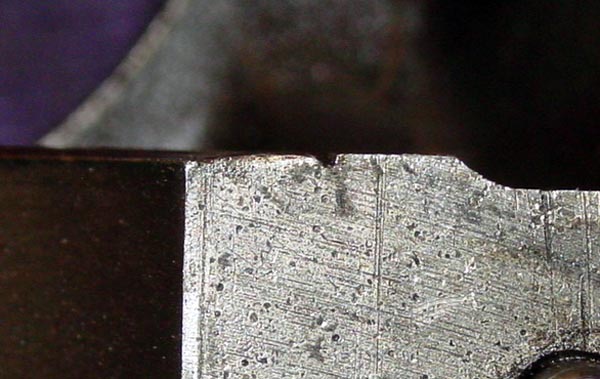

But there are still issues that trouble this engine work. Back when Aaron and I took the engine apart, we discovered the thrust washers unseated, with one of them sloshing around

the oil pan. Their absence took its toll on the crankshaft and a part of the engine block. Pictures below tell the story. The crankshaft might be repairable, assuming that a

good submerged weld could build up the face where the thrust washer fits. A ring-like ridge stands up about 0.045" from the face where the thrust washer fits. I

believe that entire depression would need building up. The ridge itself bit into the engine block in the absence of the thrust washer, and the are where the crankshaft met

the block has been beveled slightly. That area would also need squaring up.

Obviously, the question in my mind now is whether the crankshaft is salvagable — or, for that matter, the block. Mouseover the picture to see explanatory text.

|

| | |